亚麻籽预处理

获得亚麻籽后, 需要先治疗. 目的是去除杂质 (比如灰尘, 稻草, 石头, 金属碎片, ETC。) 和亚麻籽表面的水分, 并保持亚麻籽的完整性. 常见的原材料加工步骤包括清洗, 筛分, 和干燥. 清洗过程可以包括用水清洗以去除种皮和其他杂质. 过筛的目的是除去较大的杂质和不好的种子. 干燥的目的是挥发亚麻籽中的水分,提高油的质量.

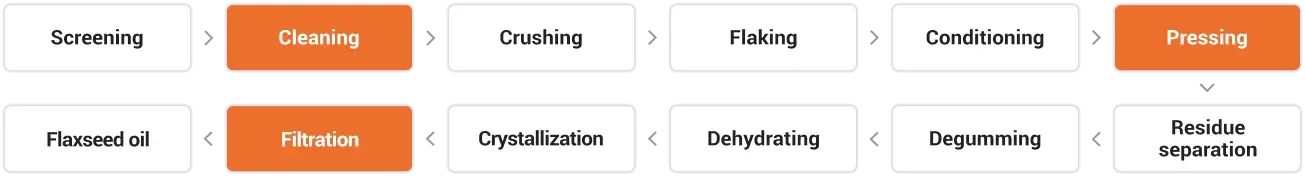

亚麻籽油, 作为富含 α-亚麻酸的健康食用油 (欧米伽3), 由亚麻籽加工后生产. 生产过程包括亚麻籽清洗, 压碎, 蒸, 紧迫, 精制, 和包装. 每100克亚麻籽可榨油30克. 100克亚麻籽油, 饱和脂肪酸占 9%, 油酸占 17%, 不饱和脂肪酸总量为 74%. 其中含有α-亚麻酸 57%, 亚油酸是 16%.

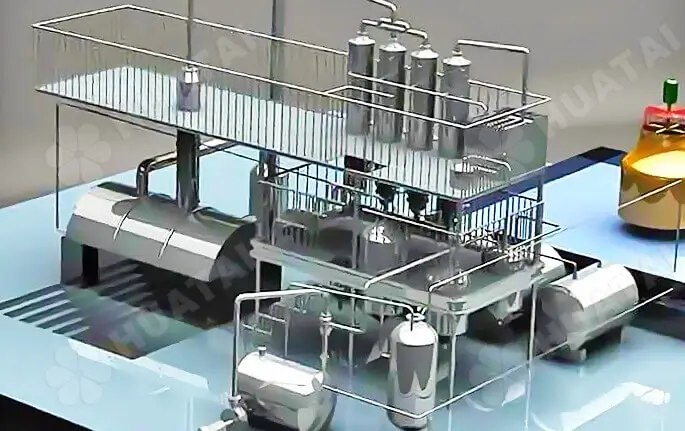

亚麻籽油广泛应用于食品中, 制药, 化妆品, 和其他领域. 华泰油机拥有丰富的亚麻籽油加工解决方案经验. 我们可以提供 10吨/天-2000吨/天 完整的亚麻籽油厂交钥匙工程.

获得亚麻籽后, 需要先治疗. 目的是去除杂质 (比如灰尘, 稻草, 石头, 金属碎片, ETC。) 和亚麻籽表面的水分, 并保持亚麻籽的完整性. 常见的原材料加工步骤包括清洗, 筛分, 和干燥. 清洗过程可以包括用水清洗以去除种皮和其他杂质. 过筛的目的是除去较大的杂质和不好的种子. 干燥的目的是挥发亚麻籽中的水分,提高油的质量.

然后将预处理后的亚麻籽压碎和蒸煮. 这是为了增加亚麻籽的表面积并调整其中较少的点, 以利于后续的石油开采. 首先, 使用破碎机进行破碎一般要求破碎后的亚麻籽颗粒大小均匀. 这样有利于油的浸出, 但不会破坏其内部结构. 然后将碾碎的亚麻籽放入锅中, 在良好的温度控制下, 湿度, 蒸、炒的时间条件.

然后, 使用活性炭和白土等吸附剂, 与亚麻籽油混合, 利用吸附剂的吸附能力去除油脂中的色素和杂质. 然后通过过滤将吸附剂与油分离, 消除任何残留固体. 脱色过滤的目的是进一步净化亚麻籽油,提高其色泽和品质.

最后, 然后对脱色和过滤的亚麻籽油进行精炼, 精炼包括脱酸, 除臭化, 和脱水. 精炼是为了除去游离脂肪酸, 醛类, 酮, 以及亚麻籽油中的其他挥发性物质和蜡质,以保证油的质量和口感. 精炼的亚麻籽油然后通过自动灌装机进行包装,以保持其质量和卫生.

华泰亚麻籽油生产线技术先进,可定制以满足各类客户的具体需求. 设备处理能力大, 故障率低, 和高效率. 其耐用性确保连续运行, 经济效益和产能最大化.

华泰低温压制工艺避免化学精炼, 而是利用水合脱胶, 活性炭除臭, 冷却, 过滤, 和脱水. 这种方法可以保持亚麻籽油的质量, 避免碱炼和高温真空脱臭等可能损害油特性的工艺.

了解华泰油机如何熟练运用冷榨方法来保持完美 1:4 亚麻酸与亚油酸的比例. 我们的流程确保您在不添加任何添加剂的情况下获得所有健康益处. 观看并探索我们用于原始亚麻籽油生产的交钥匙解决方案!

获取报价